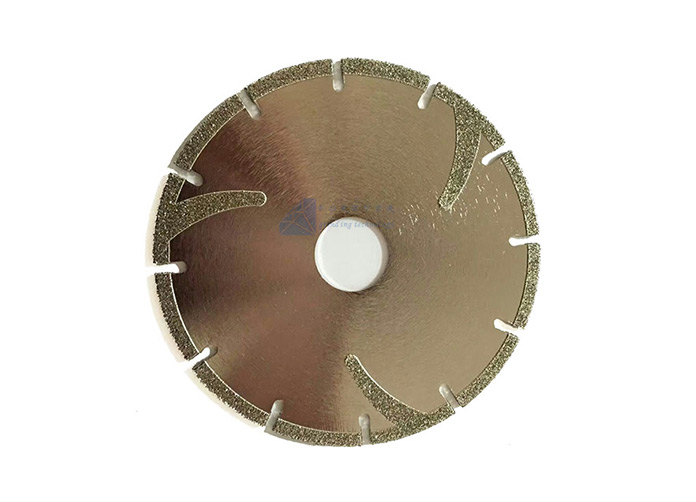

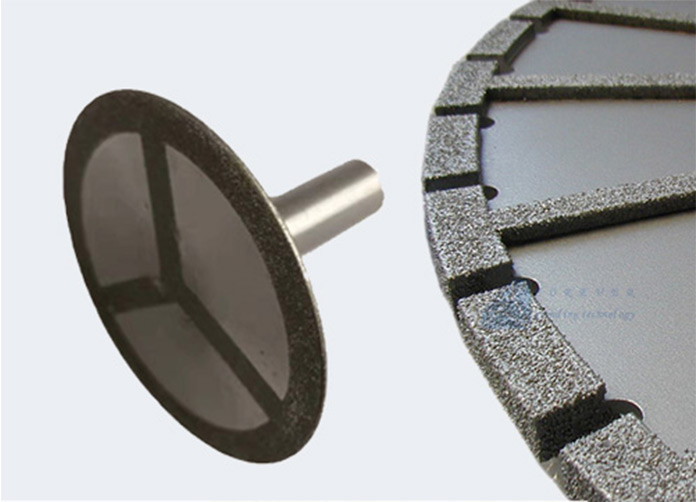

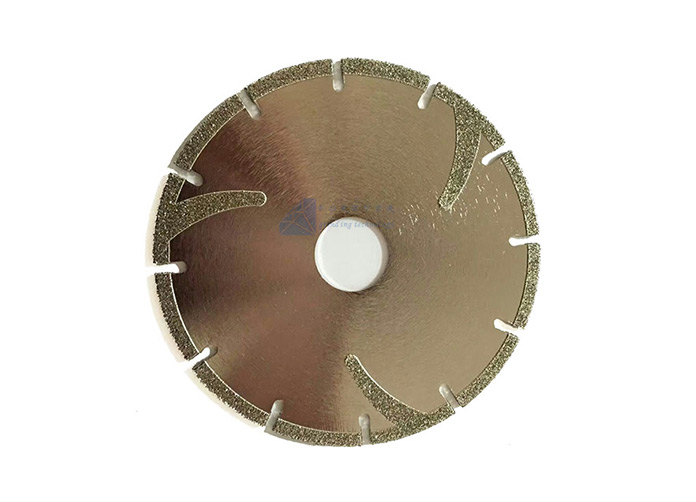

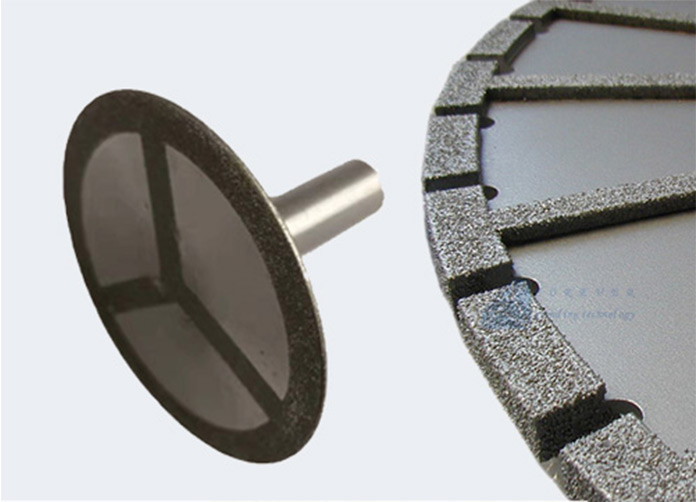

In composites, many applications benefit from the use of industrial diamond for cutting, drilling, profiling, sanding, polishing, etc. because it allows faster machining, longer tool life, and allows precise tolerances of shape and size. In the electroplated bond, the grain is bound to the body by an electroplated coating (preferably nickel). The high strength of the electroplated bond allows the bonding layers to be thin and a larger proportion of the grain to protrude.

Name: composites grinding tools

Type: 1A1R, 1A1

MOQ: 2pcs

Send us email

forever@forever-superabrasives.comCall us

8619937107349In composites, many applications benefit from the use of industrial diamond for cutting, drilling, profiling, sanding, polishing, etc.. Because it allows faster machining, longer tool life, and allows precise tolerances of shape and size.

Grinding composite materials can be a challenging and costly task, especially if you need to produce clean and accurate products. If you are keen to reduce the cost of your Diamond Tooling but do not want to compromise on innovation and quality, look no further than the superior electroplated diamond tools developed by our R&D department in collaboration with our customers, then you will find how the innovative electroplated diamond tools can optimize your production processes.

In the electroplated bond, the grain is bound to the body by electroplated coating (preferably nickel). The high strength of the electroplated bond allows the bonding layers to be thin and a larger proportion of the grain to protrude. Grinding tools with electroplated bond are characterised by excellent cutting and grinding performance. Electroplated bond grinding tools can be made in various complex shapes to achieve precision grinding.