When we talk about the processing of tungsten carbide, we will think about the grinding wheel used for grinding tungsten carbide, and the classification of tungsten carbide grinding wheels, matching what kind of grinding machine the performance of grinding wheels can be the best and so on.

In fact, the development of tungsten carbide processing technology is very fast. What kind of grinding wheels are used for grinding tungsten carbides and what are their classification? FOREVER company is a manufacturer of diamond grinding wheels, tells you exactly what carbide grinding wheels are.

There are many classifications of tungsten carbide grinding wheels. The following are several main classifications.

1. Coated carbide grinding wheel.

2. Chromium carbide-based carbide grinding wheel.

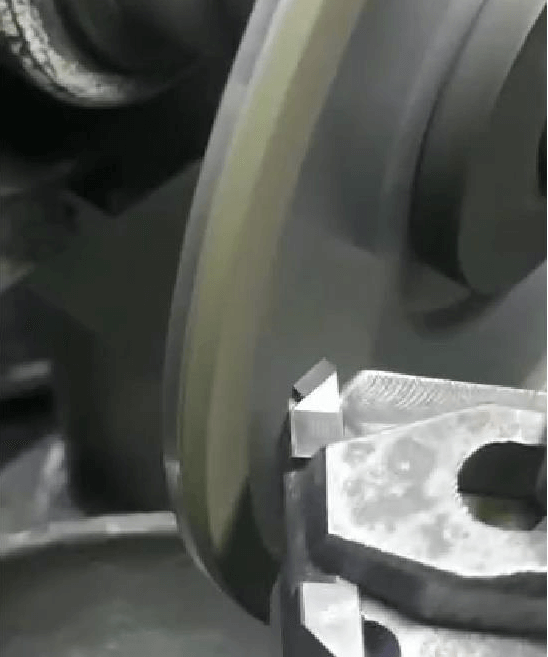

3. Resin diamond grinding wheel.

4. Titanium carbide grinding wheel.

5. Steel-bonded carbide grinding wheel.

6. TiC-based carbide grinding wheel.

Tungsten carbide has many uses, it can be used to make wear-resistant parts such as nozzle plunger, high-pressure chamber, cutting tools, mining tools and so on, which is also the reason for its popularity. Above is the classification of the main tungsten carbide grinding wheels. At present, resin diamond grinding wheels are widely used in grinding tungsten carbide workpieces.

What kind of grinding wheels are used for grinding tungsten carbide? Being a manufacturer of diamond grinding wheels, Forever company has already introduced that as above.