Tungsten carbide circular saws are designed for cutting wood.

However, the cutting effectiveness of a tungsten carbide circular saw is mostly determined by the geometry of the blade, the sharpness of the teeth, and the chip load per tooth. The process for manufacturing and maintaining the saw’s optimum geometry, sharpness, and load is referred to as circular saw grinding.

Circular saw grinding consists of three distinct but inter-related processes:

Face grinding

Side grinding

Top grinding

Advantages of circular saw grinding:

1.Maintains the uniform height and width of the teeth

2.Improves the blade’s entry angle into the board, thereby enhancing the quality of the finish

3.Maintains straight tooth sides and sharp cutting corners

4.Optimizes the blade’s circularity and concentricity

5.Reduces cutting time thereby consumes less energy

6.Sharper tooth sides produce better cuts

Choosing a diamond wheel for circular saw grinding

Forever manufacture a complete range of diamond grinding wheels, specialized for face, side, and top grinding. The unique Forever wheel design, combined with the technical use of advanced materials, enable Forever to offer a superior suite of diamond grinding wheels that match the most stringent finishing requirements.

All Forever diamond grinding wheels for servicing the saw production industry, can be supplied in either a single, dual, or triple-layered rim configurations, to support extra fine finishes, combined with superior wheel service life and less machine loading during the grinding process.

Face grinding

Face grinding sharpens the face of the teeth on tungsten carbide circular saws. It is the first stage in the 3-step process for grinding blades (see side grinding, top grinding).

Saw category

Tungsten carbide circular saws

Reasons for side grinding:

1.Maintains the uniform height of the teeth

2.Improves the blade’s entry angle into the board, thereby enhancing the quality of the finish

3.Maintains the uniform width of the teeth

4.Maintains straight tooth sides and sharp cutting corners

5.Reduces cutting time

6.Consumes less energy

Choosing a diamond wheel for facing

Thinner diamond wheels are best suited for face grinding a saw with narrow gullets.

When choosing a diamond wheel for facing, the number of teeth on a saw determines the dimensions of the diamond wheel’s rim. Saws with large amount of teeth require thinner wheels than saws with less teeth.

Forever supports diamond grinding wheels down to 1.5 mm in rim width, and a 15° rim angle.

Most commonly used Forever face grinding diamond wheels:

4V9

4A9

Side grinding

Side grinding sharpens the sides of the teeth on tungsten carbide circular saws. It is performed after face grinding

Saw category

Tungsten carbide circular saws

Reasons for side grinding:

1.The tooth sides of a trim saw blade must be maintained in a sharp condition because they have to cut through the board’s cross grain fiber

2.Sharper tooth sides produce better cuts

3.Maintain a uniform tooth width to reduce scratching and circular markings on the wood

4.Maintain straight tooth sides and sharp cutting corners

Choosing a diamond wheel for side grinding

When selecting a side grinding diamond wheel, it is worth noting that the performance of the blade is mainly determined by the diamond wheel’s ability to create sharp tooth sides and a superior surface finish.

Choose a very fine diamond wheel that is soft enough to produce a clean cut. Thinner diamond wheels are more suitable for side grinding than wider diamond wheels because they exert less pressure on the blade and reduce the risk of blunting the corners of the tooth.

Most commonly used Forever side grinding diamond wheels:3A1

Top grinding

Top grinding sharpens the tops of the teeth on carbide circular saws.It is performed after side grinding.

Saw categoryCarbide circular saws

Reasons for top grinding:

1.Alternate top bevel blades shear across fibers, therefore to prevent erratic cuts, it is imperative that the blade’s teeth are accurately ground to a uniform height

2.Optimizes the blade’s circularity and concentricity

3.Maintains a uniform chip load per tooth

4.Creates a keener cutting edge which enhances the blade’s ability to penetrate the wood

5.Creates cleaner cuts, thereby consumes less energy

6.Reduces the frequency of cutting off track

7.Reduces kickbacks

Choosing a diamond wheel for top grinding

When selecting a top grinding diamond wheel, choose a diamond wheel that is least likely to cause any distortions to the teeth’s uniform height, hooks, or rake angles. Variations in uniformity can adversely effect the chip load per tooth and inevitably decrease the saw’s cutting ability.

To improve the overall performance of the saw and reduce the frequency for blade sharpening, choose a diamond wheel that produces a fine surface on the tops of the teeth.

Most commonly used Forever top grinding diamond wheels:

6A2

14A1

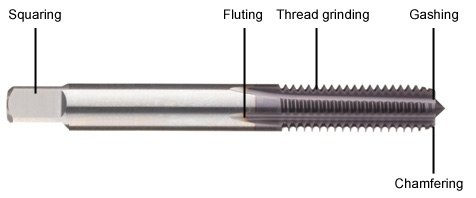

Thread grinding

Thread grinding is the process for sharpening tungsten carbide router bits.

Forever provide an innovative array of specially designed diamond wheels for the five thread grinding operations:

1.Squaring

2.Fluting

3.Thread grinding

4.Gashing

5.Chamfering

Squaring

To be defined

Fluting

Maintains the optimum depth of the flute, known as thinning the web

Thread grinding

Reduces router tear-out and minimizes the potential for splits along the grain

Gashing

Eases the profile bit’s ability to penetrate the grain

Chamfering

Maintains the cutting bevel

Choosing a diamond wheel for grinding profile cutters

Select a diamond wheel with either fine or extra fine grits. Choose a diamond wheel that is narrow enough to penetrate the flutes closest to the shank.

Forever diamond wheel recommendations

All Forever diamond grinding wheels for servicing the saw production industry, can be supplied in either a single, dual, or triple-layered rim configuration, to support extra fine finishes, combined with superior wheel service life and less machine loading during the grinding process.